YELLOW #1

New to Klingspor’s product range

Klingspor keeps the finger on the trigger: We continue to develop new solutions for a wide range of application areas. Here you will find an overview of some of the latest products that have been added to enhance Klingspor’s portfolio.

Container for the scroll indicator

(Will be hidden in the published article)

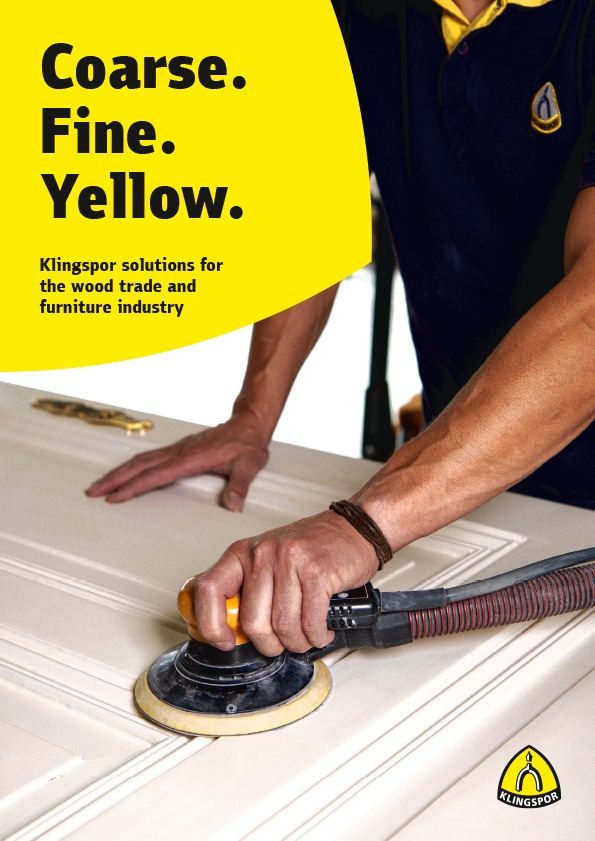

Get ready for serious action!

The new aggressive abrasive belt CS 911 X saves you time when sanding parquet floors.

Mission: Mastering price and performance

The new high-performance abrasive belt for stainless steel and high-alloy steels.

Small idea, long-lasting effect!

The new abrasive belt cleaner SBR 100 extends the service life of abrasive belts and abrasive discs.

Get ready for serious action!

Get ready for serious action!The new aggressive abrasive belt CS 911 X saves you time when sanding parquet floors

The parquet floor made of end-grained wood that adorns the seminar room of the new Klingspor Training Academy catches the eye of many visitors: The warm, light wood tone and the striking grain give the room a flair without equal. The floor owes its bright shine to its elaborate refurbishment. The specialist contractor entrusted with this task brought out the best the old floor had to offer and also tried out Klingspor’s new abrasive belt CS 911 X on the parquet floor sander during the rough sanding of the floor. The parquet floor professional was impressed with how aggressive this belt is: “Wow, it really goes at it.”

High performance with ceramic aluminium oxide

Klingspor originally developed the CS 911 X for metalworking. However, thanks to its aggressive grinding characteristics, the CS 911 X is also ideally suited for the efficient rough and intermediate sanding of hardwood, a classic application of parquet floor installers. Primarily responsible for its outstanding stock removal rate is the high-quality abrasive grain made of ceramic aluminium oxide. “This means that you can remove a significantly larger amount of material in one pass compared to an ordinary aluminium oxide abrasive belt,” explains Ralf Müller, Product Manager at Klingspor. As a result, parquet installers need fewer sanding passes, saving both time and money.

Unbeatable service life and price

Better still, the premium ceramic aluminium oxide also gives the CS 911 X a service life that trumps that of belts furnished with conventional aluminium oxide and zirconia. Its aggressiveness remains high to the end. Ralf Müller recommends the new high-performance abrasive belt to anyone who is looking for a continuously aggressive and attractively priced belt for parquet floor sanding – whether for refurbishing or installing new parquet flooring.

The CS 911 X is available in grit sizes 36, 40, 50, 60, 80, 100, and 120. “The rough sanding of parquet floor often starts with grit size 24”, says Ralf Müller. “However, our tests have shown that the CS 911 X already has a grit size of 36 on account of its aggressiveness.”

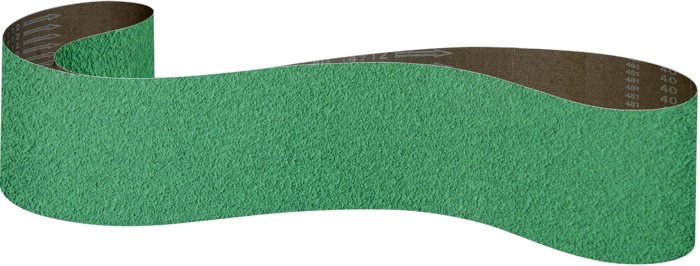

Mission: Mastering price and performance

The new high-performance abrasive belt for stainless steel and high-alloy steels

When mountaineer George Mallory was asked why he intended to climb Mount Everest, his short and confident answer was: “Because it is there.” In a similar way, the answer to the question as to why the new ceramic abrasive belt with a backing made of a cotton-polyester blend challenges other abrasive belts might be: Because it can. After all, the new, particularly powerful abrasive belt is easily on par with a great many higher-priced belts.

Challenge mastered with flying colours

Trials have revealed that the new CS 913 X achieves excellent results when used for grinding stainless steel. There are certain applications where the CS 913 X easily matches the performance of high-priced and aggressive ceramic belts sold by top competitors,” reports Yusuf Acikel from Business Development. Pitted against a leading competitor in a comparative test, we were able to consistently deliver greater stock removal. In this comparison, we also came out on top with a significantly better price-performance ratio.

Perfect all-rounder for the metal industry

The abrasive belt is a universally applicable workshop belt that is equally ideal for use on stainless steel and high-alloy steels. Among other things, it is an excellent choice for use in the cutlery and tool industry, in the pipe and hydraulic industry, as well as in service centres and in container construction. Its stiff poly-cotton backing lets it deliver great stability and high abrasion rates in industrial applications. These characteristics qualify it as a challenger of many higher-priced products. Aside from being a good pairing with narrow and long belts, the product is also ideal for use as a file belt.

Available in grit sizes of 40, 60, 80, 100, and 120, the CS 913 X is perfect for rough and intermediate sanding at low to medium tool pressures. Thanks to multibond, it generates only low temperatures in the abrasive zone.

Small idea, long-lasting effect!

The new abrasive belt cleaner SBR 100 extends the service life of abrasive belts and abrasive discs.

Every carpenter is familiar with this: After a while, an abrasive belt clogs up and suffers a loss of its abrasive performance. A subsequent increase in sanding pressure to achieve better stock removal may then, at worst, burn the surface. It is impossible to avoid clogging, even if the grain type, grit size and coating density have been selected perfectly, the machine is properly adjusted, and the dust extraction system works well.

But beware: Clogged does not necessarily mean worn

Klingspor carries a small tool that restores clogged abrasive belts to their original sharpness: the abrasive belt cleaner SBR 100. Boasting a length of 21.5 centimetres, the bar is made of pure natural rubber and works small miracles. When held up to the running abrasive belt and pulled over the belt surface, it literally brushes out the clogged belt. “The abrasive belt cleaner is sure to pull out nearly everything that becomes stuck as swarf, paint remnants or similar residue,” explains Hartwig Dangendorf, Product Manager at Klingspor. After it has been cleaned, the belt will sand like new again. After all, clogged does not equal worn, spells out Dangendorf: Abrasive grain does not wear out quickly – especially not in wood sanding applications. A drop in abrasive performance can usually be attributed to clogging – rather than wear.”

Simple helper – long-lasting effect

The abrasive belt cleaner SBR 100 makes it possible to considerably extend the service life of abrasive belts and abrasive discs. A simple and affordable helper for joineries and hobby carpenters, it also makes a sizeable contribution to sustainability.

Container for the dynamic page

(Will be hidden in the published article)

Container for the dynamic page

(Will be hidden in the published article)